MC2 Energy Supervision

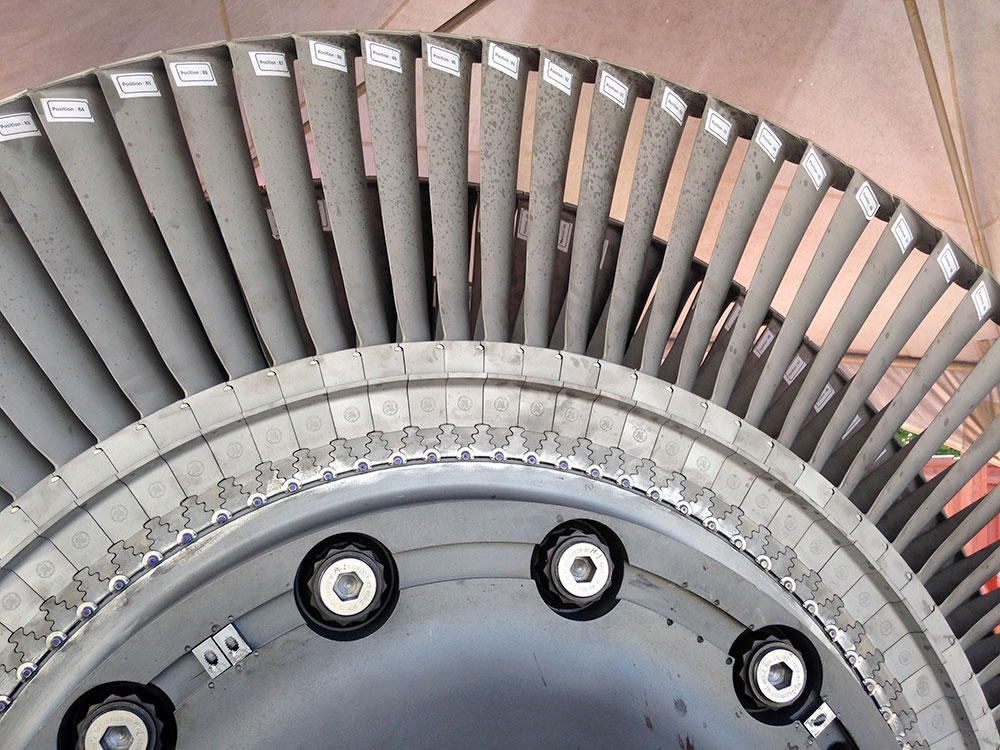

Blading Specialist

Supervision of removal and reassembly of turbine blades according latest assembly specifications. Spare part analysis and recommendations.

Inappropriate assembly of blades might cause increased vibrations, premature wear or failure of the blades.

Laser alignment

Our experts will carry out laser or conventional alignment by using latest technology equipment.

MC2 Energy Inspection

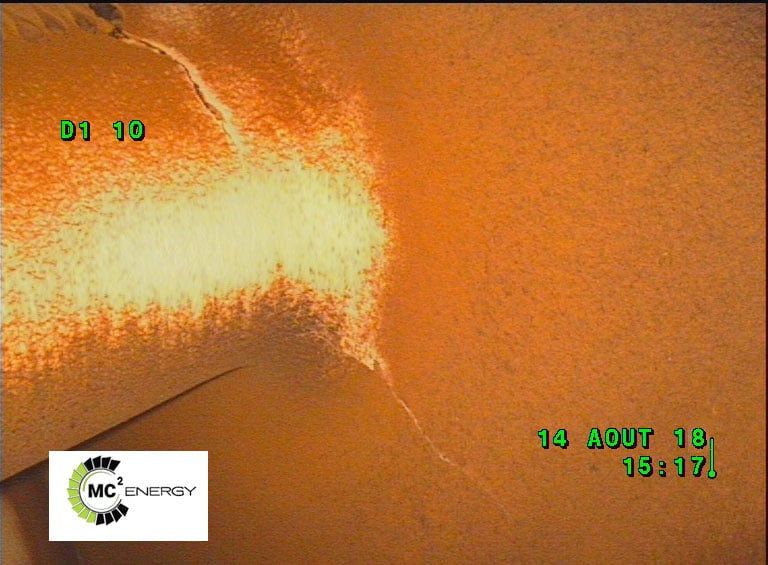

Borescope inspection

The manufacturer prescribes a borescope inspection of the units during each planned combustion inspection according detailed instructions,see here.

However, our experts can also execute a borescope inspection for investigation in case of one of the following events:

- Pressure loss CPD

- Power loss

- Irregularly increased vibrations

- Unusual temperature between the discs

- Standstill time of the shaft too fast (except the problems which can occur involving auxiliaries and power reducer or lubrication, all of which have been preliminary investigated)

A borescope inspection performed by experienced engineers and proper equipment is an efficient tool to prevent damages and thus avoiding operating losses as a result of these damages. At the end of the inspection, a preliminary report will be handed over to you by our expert on site in which major repair works are identified to allow you to anticipate appropriate actions. A detailed report with all our recommendations will submitted to you shortly after.

MC2 Energy Expertise

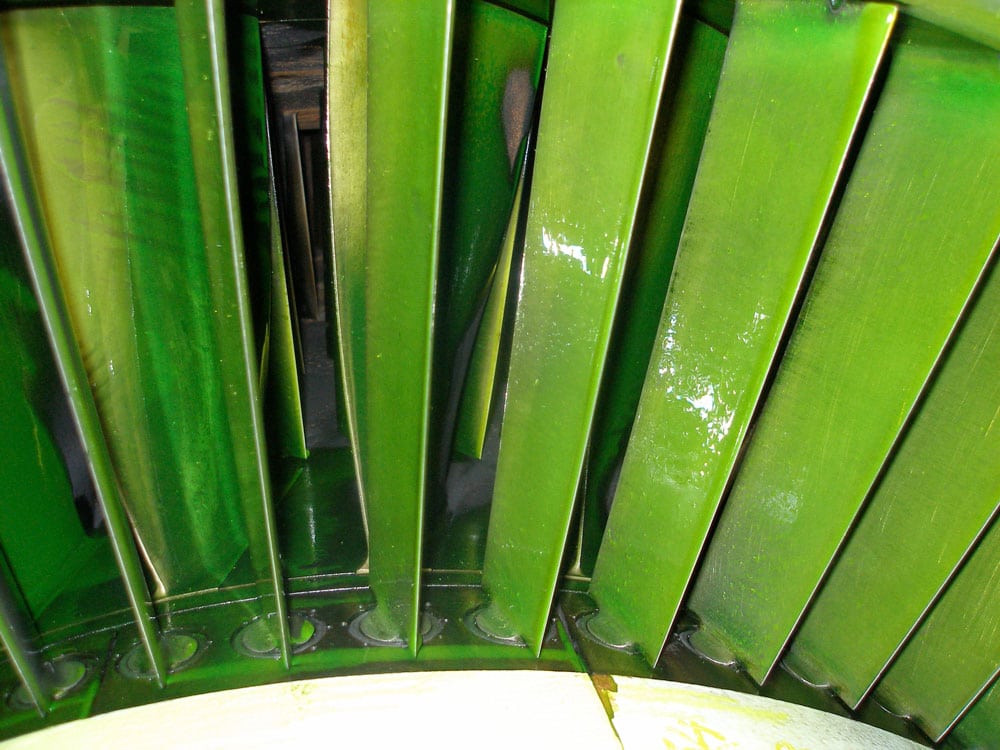

CO² cleaning

For the various assessment phases it is necessary that the rotor surfaces are clean and free from oxidation, grease and residue. MC2 Energy recommends to use dry ice cleaning for its easy application and getting the best results.

Moreover this procedure not let any particle from rotor critical areas (cooling system clogging risk, extraction).

MC2 Energy Expertise

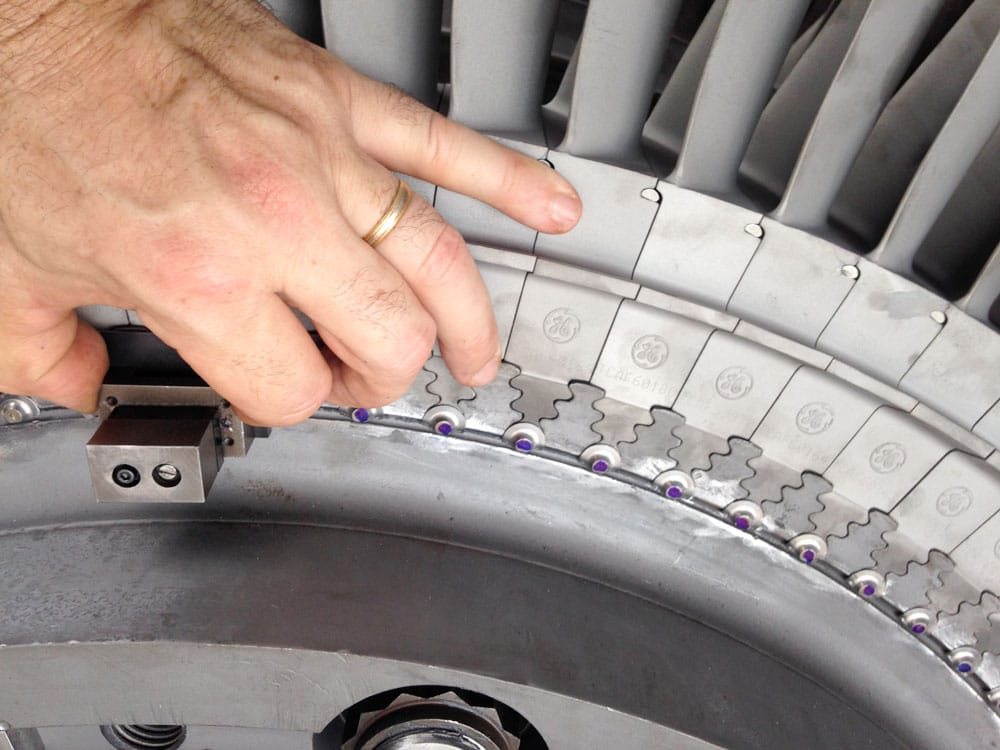

Compressor blade inspection

Poor quality conditions of the air (e.g. humidity, saline air, foreign substance) absorbed by the compressor is able to cause minor of even major damages to the stator and rotor blades.

MC2 ENERGY will perform various assessments executed by our field service engineers :

More details +MC2 Energy Expertise

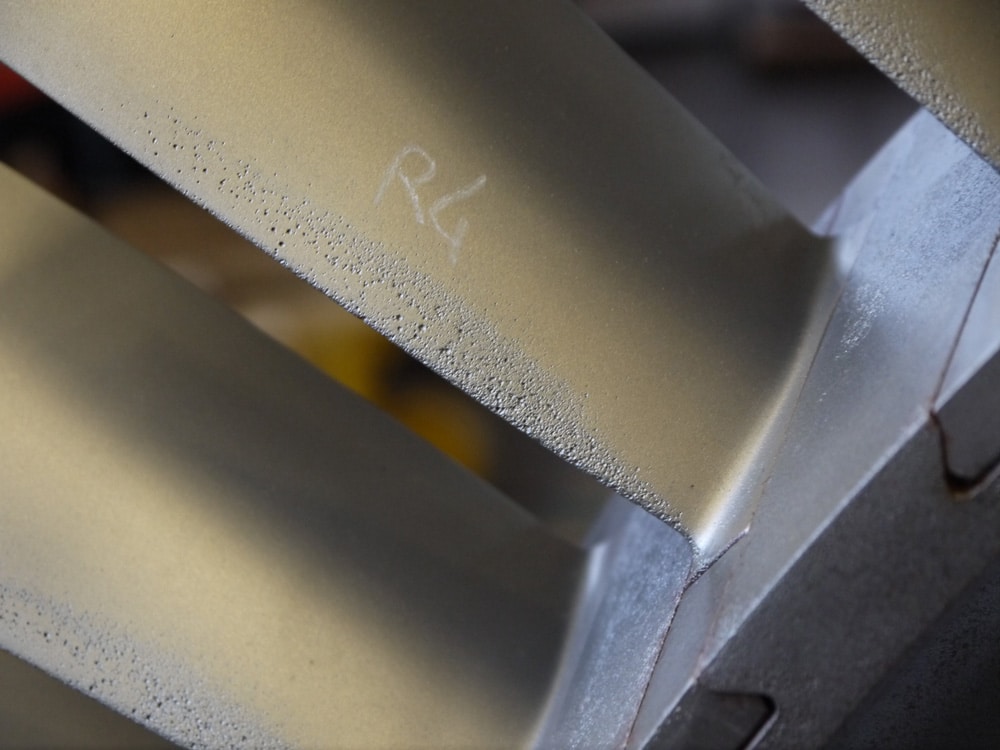

Rotor journal bearing inspection

Major vibration problems, poor quality of lubricating oil can deteriorate the journal bearings and bearings.

Our experience and specific equipment enable us to determine the severity of the damages found on the bearing such as scratches or corrosion pitting.

This in order to decide on the repair level which will have to be considered :

- Onsite repair in case of minor deterioration

- Workshop repair in case of major deterioration (a balancing check will be required/ the rotation axis could be potentially changed).

MC2 Energy Expertise

Turbine wheel inspection

Too much clearance between the blade and the turbine wheel can drive out a seal pin or is able to cause premature wear of mechanically critical areas between the blades and turbine wheel. These defects can provoke major damage in the hot end section of the turbine.

Preventive controls performed by MC2 ENERGY:+